The end goal of building a house is not just to ensure that it’s functional, but that it’s also aesthetically pleasing too.

Tiling and rendering are two of the many things you can do to improve both the quality and the look of your property.

But how do you tile and render with the longer term in mind? Which products ensure quality and durable results from these processes, especially when it comes to your property’s nonporous surfaces?

In this two-part series, we will talk you through everything you need to know to make your home tiling and rendering projects a success both today and down the track.

First, let’s talk about permanent formwork.

Before we discuss tiling and rendering, it’s important to understand the materials that come before them. One of these is permanent formwork.

Permanent formwork consists of braces and moulds that hold concrete as it sets, eliminating excessive concrete waste, labour to de-install formwork once the concrete has cured, and afford water resistance in the case of uPVC permanent formwork. Permanent formwork speeds up the building process and helps you save money by removing the need for temporary formwork and falsework. In addition, permanent formwork promises to deliver high-quality finishes for your home and minimise the risks of hidden faults or defects.

Some of the most popular permanent formwork we have in Australia are made of products from Dincel, RediWall, Rise Products, Permaform and Zeggo.

What’s the role of permanent formwork in tiling and rendering?

Permanent formwork is often made of fibro board and galvanised steel.

The problem with this, however, is that you can’t easily apply acrylic render, brick biscuits, stone cladding and ceramic tiles to this plastic surface – all the things that turn ordinary looking concrete into something more attractive in your home. Unfortunately, these materials can’t stick onto the nonporous surface of the plastic formwork.

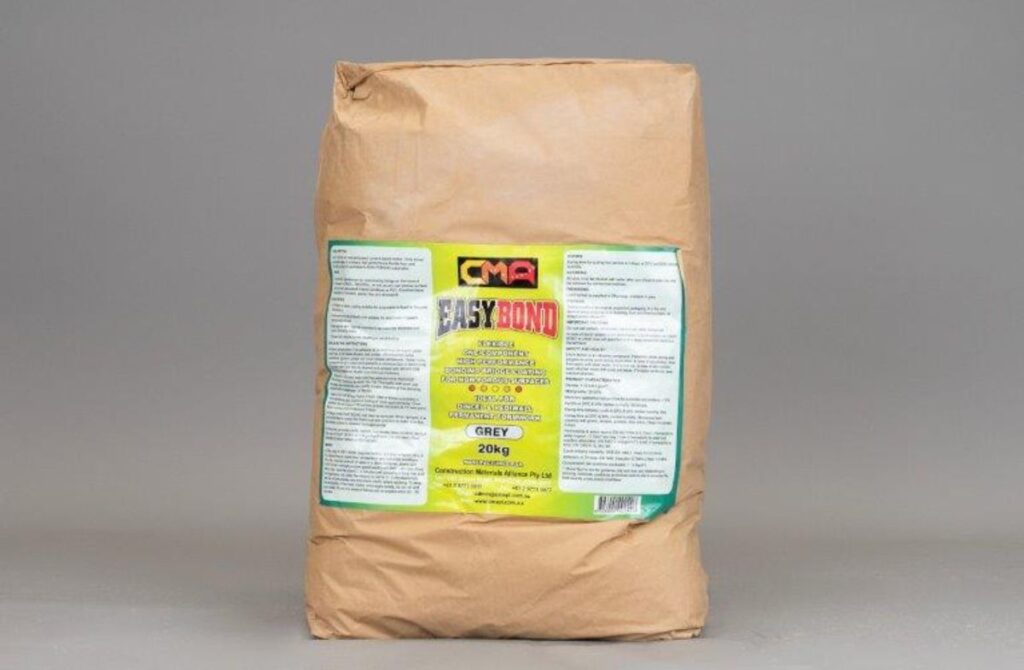

So, what’s the solution? Simple – (SWP) Scientific Waterproofing Products’ EASY BOND!

The right product for your tiling and rendering requirements

EASY BOND is an ideal bridging coat for your Dincel, RediWall, Rise Products, Permaform and Zeggo permanent formwork.

It is a one-component cement-based mortar that provides a high-performance flexible key coat bonding bridge when mixed with water. EASY BOND sticks to the plastic formwork, and at the same time, enables you to adhere acrylic render, brick biscuits, stone cladding and ceramic tiles to it.

As an anti-fracture membrane between the substrate and other finishing coats, EASY BOND allows you to tile and render with ease and convenience. It does not require any primer, scuffing or sandblasting, and is also suitable for application even in poorly ventilated areas.

Bonus tip: Waterproof your permanent formwork

The other critical thing about permanent formwork is it has to be waterproofed at a point called the “cold joint” – which is the intersection where the permanent formwork meets the floor.

Waterproofing is done before applying EASY BOND to the permanent formwork in order to guarantee the durability and quality of your tiling and rending project.

At SWP, we offer a wide range of superior products that can help you address cold joints in permanent formwork. Here are some of the water solutions we offer:

- Drizoro MAXSEAL® FLEX – is a two-component product. Once applied and cured, it provides a non-toxic, flexible and waterproof coating with very high adhesion on those common substrates in construction-concrete, natural and artificial stone, traditional mortar plasters, bricks, concrete blocks, Hebel® and more.

- Drizoro MAXMESH – This is a woven fibreglass mesh designed for use with waterproofing coatings to reinforce and strengthen areas that are subject to movement.

- Drizoro MAXJOINT ELASTIC – MAXJOlNT ELASTlC is a two-component product. When both components are mixed, an elastomeric product with high bond strength is achieved that is suitable for sealing joints and cracks in concrete, pre-cast Elements, mortars and bricks.

These last two products complement each other.

MAXMESH is put between the first and second coat of MAXSEAL® FLEX, while MAXJOINT ELASTIC is utilised to anticipate and address possible movements in your permanent formwork.

Just keep in mind that the information above must be used in conjunction with the appropriate technical data bulletins and material safety data sheets available from our office or website.

Choosing the right products for your tiling and rendering needs

To find out what other products suit your specific tiling and rendering needs, read the next blog in this series.

Select quality products for tiling and rendering on nonporous surfaces

Our team at SWP is here to provide you with the right waterproofing for your unique needs. We offer a number of Drizoro cement-based waterproof coatings and other waterproofing solutions for all your building, maintenance and restoration requirements.

Aside from local Drizoro resellers and applicators, our products are also available at Paint Place branches.

Each Paint Place store is locally owned and operated, so you can always expect expert advice and professional service. Their specialists can also help you with all of your painting project needs, including colour advice and step-by-step guidance.

If you’ve got other questions or issues around waterproofing, don’t hesitate to contact us today! SWP is always committed to delivering the right solution to any problem or application.